Lathe Type Auger Flight Machine

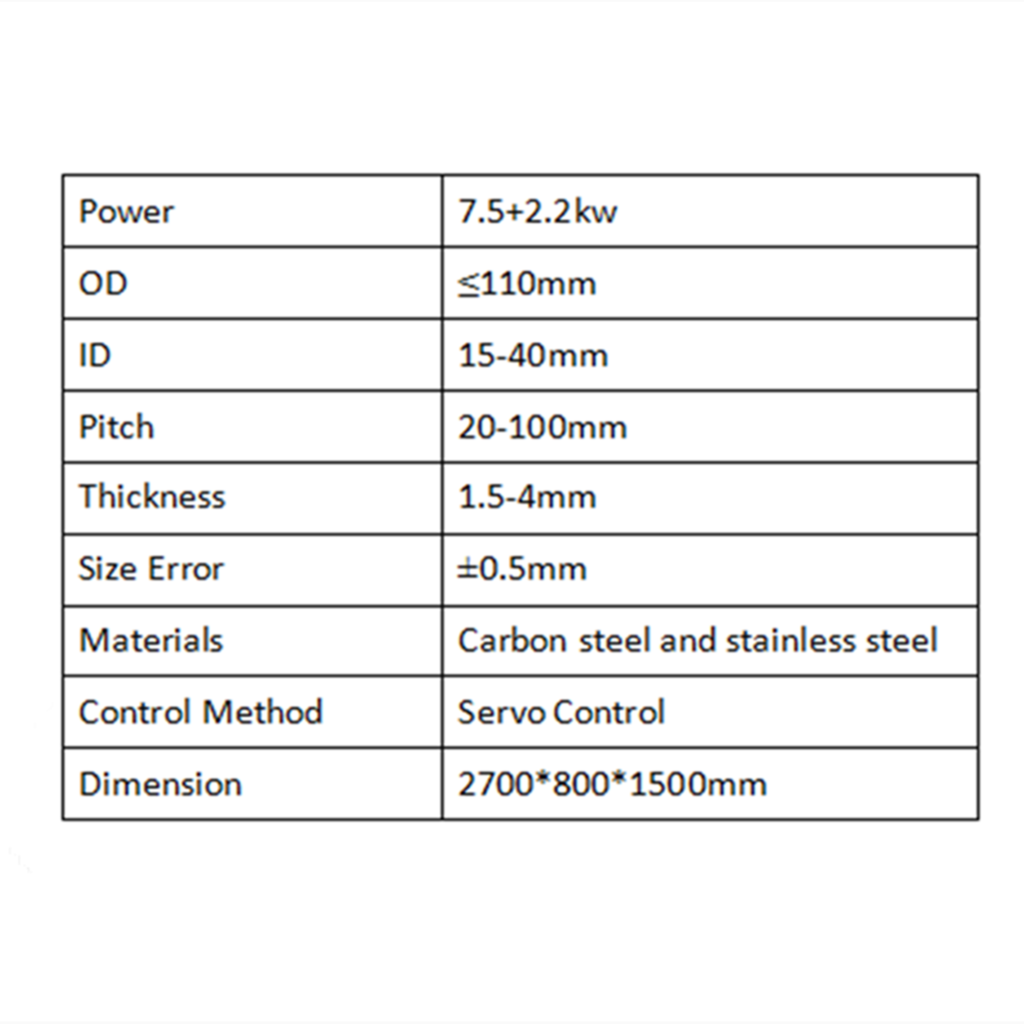

This machine produces same thickness screw flights, and it mainly includes control system and mechanical system. The control part is servo system to produce different size screws; Put data(ID, OD, and pitch) on the screen, the mechanical parts will be adjusted automatically, the could produce corresponding size screw. The mechanical part includes slipping track, lead screw, supporting frame and dabber. To produce different size screw, it needs to change different dabber. Different pitch with match different speed.

The machine operates on the principle of a lathe, where a piece of metal is shaped and cut to form the spiral flights with exacting precision. This process involves the deformation of a flat steel plate into a helix of desired diameter and pitch, ensuring a snug fit and seamless integration into the screw conveyor’s shaft. Unlike traditional methods, which can be labor-intensive and prone to inaccuracies, the lathe-type auger flight machine automates the process, significantly enhancing production speed, consistency, and quality of the flights.