What are the methods to increase the wear resistance of auger flights?

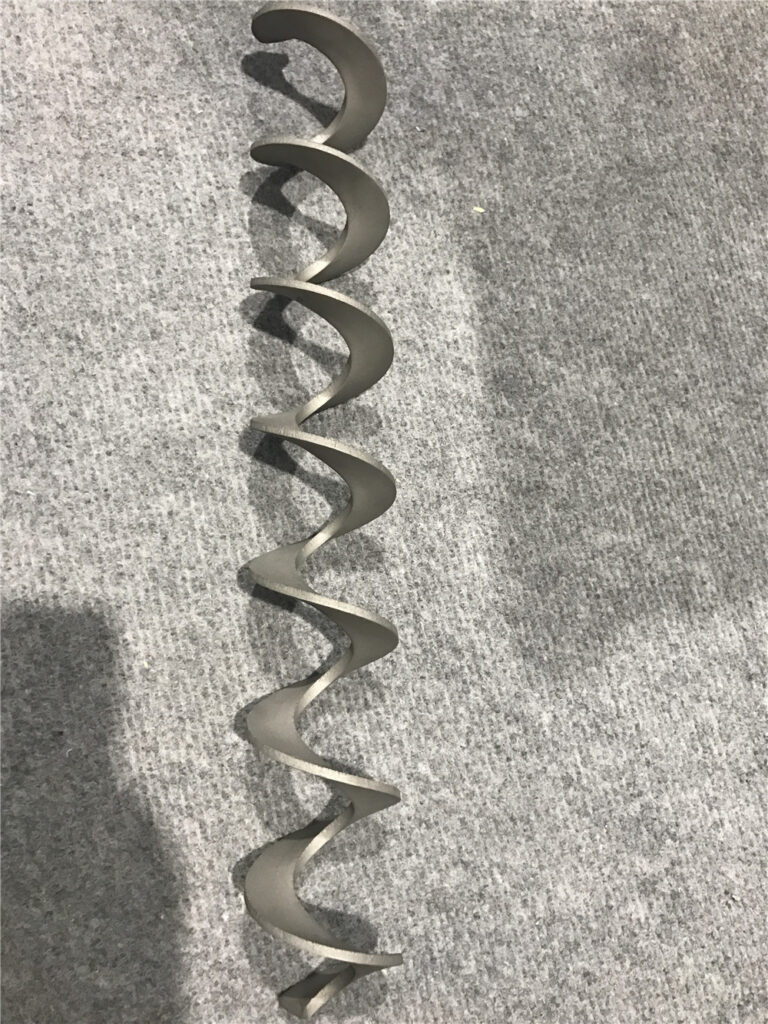

Auger flights are consumables. As the main accessories of screw conveyors, they change the displacement of materials by rotating continuously during work. Some auger flights are also used for mixing. In the silo, the materials rotate continuously through two auger flights to mix the materials. No matter which type of auger flight, it will rub against the materials continuously during work, and friction will cause loss. Over time, the auger flights will appear such situation: falling off, perforating, and etc. In more serious cases, it should replace new auger flights. How to increase the wear resistance of auger flights is a concern problem of final users. Solving this problem could achieve twice the result with half the effort.

From a cost perspective, the thickness of the auger flights depends on the material being conveyed. For materials with lower density, it could select thinner auger flights, and for materials with higher density — granular or blocky materials, it could select thicker auger flights.

The first method to increase the wear resistance of auger flights is to increase the thickness of the auger flights, increasing 2-4mm on the original basis, which can directly increase the wear resistance of the auger flights and increase the service life.

The second method is to change the material of the auger flights. The difference in materials is also an important factor in determining wear resistance. Commonly used materials include carbon steel, manganese steel, and stainless steel. Carbon steel has lower wear resistance, while wear-resistant steel and stainless steel have better wear resistance. If the service life of a certain auger flight is short, it can be replaced with a better material to improve wear resistance and service life.

The third method to increase the wear resistance of auger flights is to weld a high-wear-resistant material or fix a wear-resistant liner on the outer circle of the auger flight. When the screw conveyor is working, the auger flight and the shaft rotate at high speed, the material is affected by gravity and centripetal force, and the material has the most contact with the outer circle of the auger flight. Therefore, the outer circle of the auger flight is a place that is prone to wear. Only the outer circle needs to be reinforced to increase the wear resistance. For example, a flight sand washing machine is to reinforce a circle of wear-resistant material liner on the outer circle of the auger flight and fix it with bolts. This not only increases the wear resistance, but also makes it easy to replace after wear.