How to make big diameter augers on the machine?

Auger flight forming machine is to produce sectional augers. The auger flights are the important parts of screw conveyor, the function is to convey materials. There are many types of screw conveyor, and the model is generally determined by the diameter of auger outer tube. The diameter range is from tens of millimeters to two meters, with a wide span. To process a sectional auger flight, it is necessary to cut the materials firstly, use plasma CNC flame or laser cutting to cut out the fan-shaped raw materials, and finally extrude and form to obtain a complete auger flight.

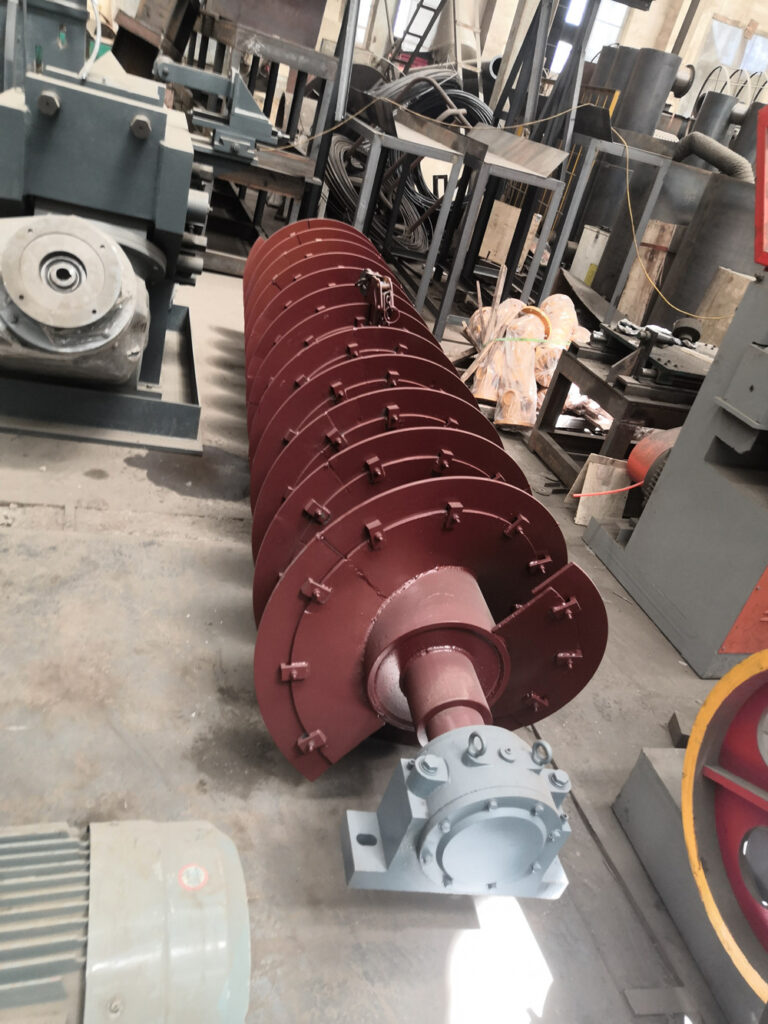

In conventional auger flight processing, qualified auger could be easily processed by selecting a good forming mold on the machine in advance, installing the mold, and adjusting the processing position. When making large-diameter auger flights, the width of the auger flight should be checked firstly, which is half of the difference between the outer diameter and the inner hole. The mold is selected based on this width data. The mold length has a certain range, exceeding this value will also exceed the machine processing range of the auger. At this time, the blanking steel plate should be cut and cut into two parts by flame cutting from the center of the outer diameter and the inner hole. In this way, the width of the blanking material is smaller than the length of the mold to meet the processing requirements. The next step is to process the two parts of the auger flight in turn. During processing, pay attention to the consistency of the pitch. At last, the two auger flights are welded with the inner circle of the large spiral and the outer circle of the small spiral to form the required spiral blades.

When processing large-diameter auger flights, another situation will occur. The outer diameter and inner diameter of the auger are both large, and the width is narrow. If the conventional cutting method is used, the middle part will become waste after cutting, and the waste area is too large, wasting materials. In order to save materials, the auger can be divided into two parts for cutting, and divided into two from the middle, so that they are arranged in rows, which can save half of the waste and reduce the processing cost of auger flights.